R&D

SMART illuminates the future of bike lights with our state-of-the-art research and development facility and modern production methods.

A few key features include:

• We have developed our own Surface-mount technology (SMT) machine to quickly and flawlessly produce electronic circuits. The SMT method allows us to mount electronic components directly onto the surface of printed circuit boards. The results are smaller internal components, faster production capabilities and flawless quality.

• Printed Circuit boards (PCB) mechanically support and electronically connect the electronic components of Smart lights. Our automated process utilizes a robotic PCB auto welder for consistent reliability.

• Photometry is the science of the measurement of light, in terms of its perceived brightness to the human eye. Our Optics Testing Laboratory allows us to make sure our lights meet or surpass the most rigorous lighting standards as established in the EU, Germany and Denmark.

• Our Optics Testing Laboratory also includes an Integrating Sphere to assess the total radiant power of our LED lights. The resulting FL1 testing ensures accurate lumen ratings and run times.

• To make sure that our lights perform flawlessly in all the conditions that cyclists encounter, we have equipment for testing our products in extreme high and low temperatures and a salt spray lab to ensure that our lights will resist corrosion.

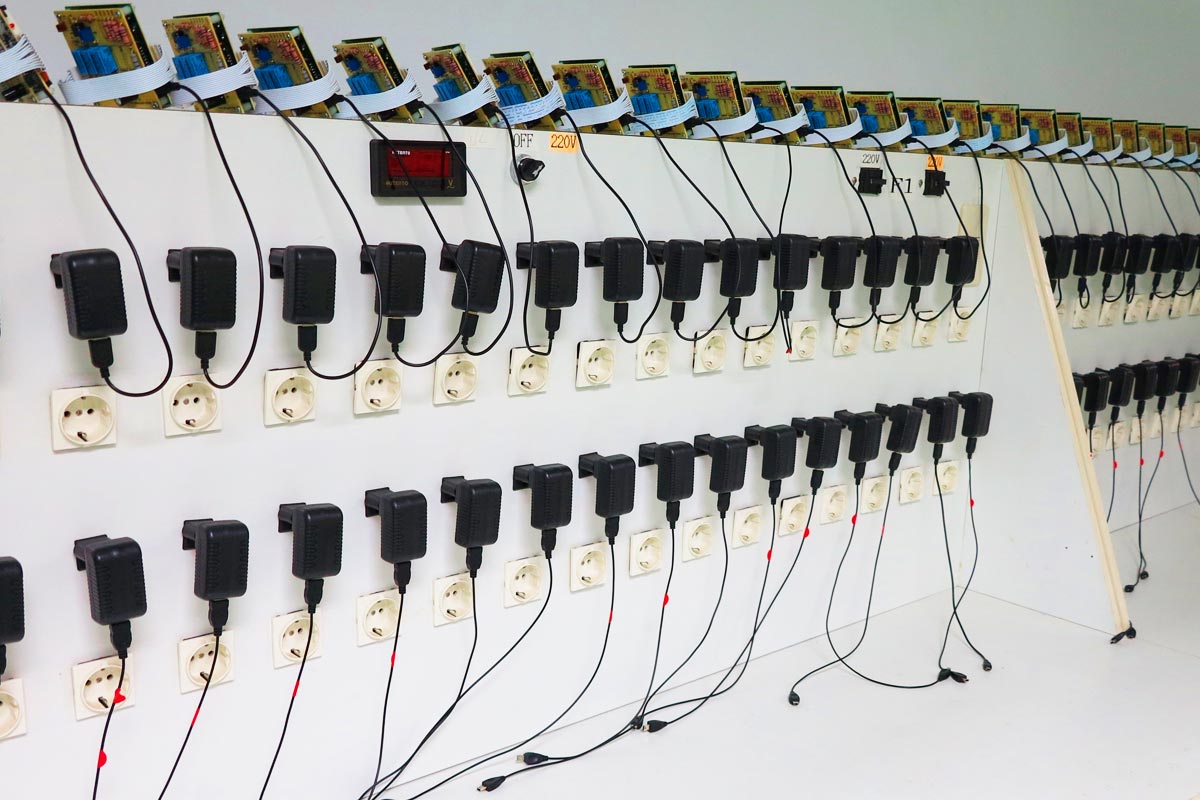

• All of our USB rechargeable lights are rigorously tested in our Recharging Test Lab. We test every light that we make.

• We utilize modern assembly and packaging techniques to guarantee accurate and swift delivery to customers world wide.

.